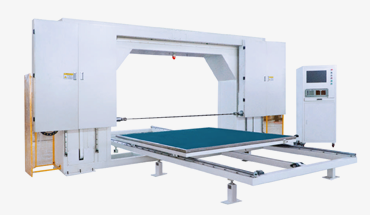

RT-HV30

The Oscillating Blade Contour Cutter RT-HV30 has both horizontal and vertical blades, enabling efficient cutting of materials like different foam material . The two blades effectively solves the challenges in cutting shapes with different foam material .

- Double blades combination : The combination of horizontal and vertical blades allows the machine to cut various complex shapes.

- Short response time :The machine has a short response time, enabling quick startup and cutting

- High processing accuracy:The machine has high processing accuracy, meeting customers’ high cutting standards

- Convienent blade replacement :Rapid blade replacement facilitates the machine’s use for operators.

Oscillating Blade Contour Cutter RT-HV30

The Oscillating Blade Contour Cutter RT-HV30 can cut more shapes compared to a single oscillating blade, and it can handle simple three-dimensional shapes in small quantities. If your clients have diverse cutting shape requirements, you can consider this machine.

The cutting accuracy of this machine is within +/-0.5. If your clients demand high precision and have a large production volume of irregular shapes, this machine is a suitable choice.

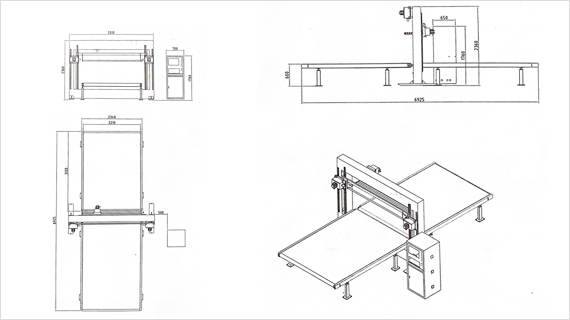

Technical Data

- Tab1

| Machine Weight (T) | 3.5 |

| Total Power (KW) | 10 |

| Maximum Cutting Size (mm) | 3000*2200*1300 |

| Blade Size (mm) | 2460*3*0.6 1600*3*0.6 |

| Cutting Speed (m/min) | 0~15 |

| AC Power Supply | 220V/380V/415V 50/60HZ |

| Accuracy(mm) | ±0.5 |

| Workbench Structure | Conveyor |

| Air pressure | 0.4-0.6MPa |

| Machine system | Windows 10 |

Three unique advantages

Equipped remote control

The equipped remote control allows for easy movement control of the conveyor belt. When this machine stops cutting materials, the Oscillating Blade Contour Cutters convenient to adjust the position of the foam block, making the cutting process more efficient for production.

Updated vibrating blade technology

The updated vibrating blade technology completely solves difficulties in cutting extremely soft, highly adhesive, and densely packed foam materials, ensuring precise cutting.

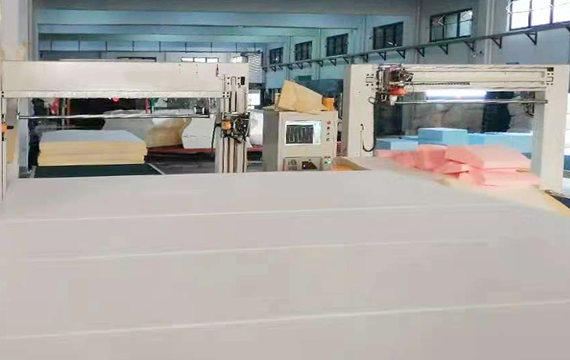

Cutting a large foam block

Cutting a large foam block typically takes a little over half an hour. While the machine is running, there’s no need for a worker to supervise constantly, addressing the issue of a limited number of workers. One machine is equivalent to the efficiency of 3 to 4 people

No dust environment

The cutting process of this machine doesn’t generate dust, resulting in no environmental pollution and contributing to the overall health of workers

Materials that can be cut

Cutting Shapes

- Cutting samples

machine installation Pictures (3)

Lorem Ipsum Dummy Text

Loading pictures

Related products (4)

It won’t generate dust because the oscillating blade effectively controls the scattering of materials during cutting. However, the specific situation may also depend on the type and density of the materials being cut

The main vulnerable parts of this machine include the blade belt and clamp teeth. The replacement time for the blade belt and clamp teeth is not fixed and is usually determined by the type of foam being cut and the machine’s working hours. In addition, there are some other vulnerable parts, such as small springs and dampers, which are typically replaced every three months.

The lifespan of the machine depends on several factors, including usage frequency, the hardness of the cutting materials, and the level of maintenance.

If the machine is properly maintained and used according to the manufacturer’s recommendations, it can typically last around 10 years.

We will send this machine in 15days after receiving 30% deposit and will deliver the goods in the container after receiving the rest 70% balance .

No, it can cut all 2D shapes but only some of 3D shapes.