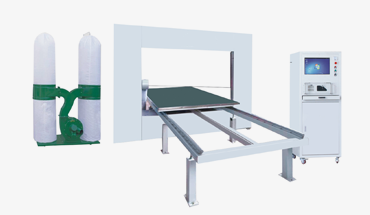

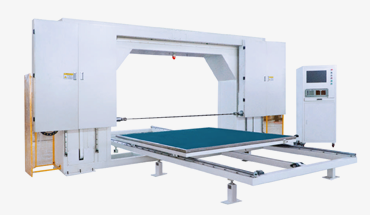

RT-631

The current model is our vertical fast wire cutting machine, capable of cutting all types of rigid foam, particularly specialized for cutting rigid foam sheets. If you are looking for a machine to cut rigid foam sheets, then this model is very suitable .

*Efficient Cutting: The machine can cut quickly and efficiently, making production much faster compared to manual cutting or other machines.

*Versatility: It works well with different types and sizes of materials, showing strong cutting capabilities.

*Waste Reduction: By controlling the cutting process precisely, it minimizes leftover materials, ensuring maximum utilization of resources

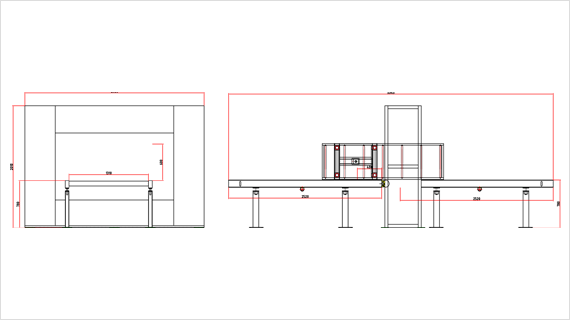

Horizontal contour cutting machine RT-631

RT-631( vertical fast wire cutting machine ) can cut rigid foam sheets into various geometric shapes, including materials like sponge, polyurethane foam, XPS extruded board, EVA, EPE, EPS, corrugated board, rock wool, floral foam, and more. Additionally, it can also trim the edges of the materials.

This equipment comes with a dust suction device, reducing environmental pollution and promoting the health of the workers. If you are considering a machine for cutting rigid foam, this option is worth considering

Technical Data

- Tab1

| Machine Weight (T) | 2.4 |

| Total Power (KW) | 8 |

| Maximum Cutting Size (mm) | 2500*1600*600 |

| Blade Size (mm) | 9600 |

| Cutting Speed (m/min) | 0~10 |

| AC Power Supply | 220V/380V/415V 50/60HZ(3phase) |

| Accuracy(mm) | ±0.5 |

| Workbench Structure | Conveyor |

| Adjust Blade to Zero | 6 Bar Pressure |

| Self-diagnostic Status | Installed |

Three unique advantages

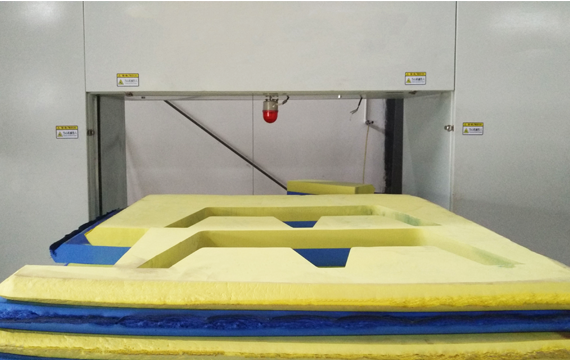

Multi-Layer Cutting

The vertical blade of fast wire cutting machine can cut multiple layers of rigid foam, creating various shapes. This meets different customers’ cutting needs, enhancing the company’s ability to take on more orders.

Precision Vertical Cutting

The short distance between upper and lower wires allows precise vertical cutting for any material, with a maximum material height of 600mm. This meets customers’ high requirements and helps the company attract more orders.

Easy-to-Learn Cutting Software

The cutting software of fast wire cutting machine is simple and easy to learn, requiring only computer operation. Operators can master it within 3 days, ensuring smooth machine use without any operational problems .

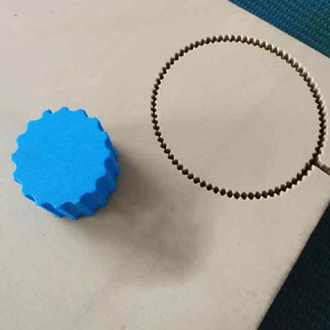

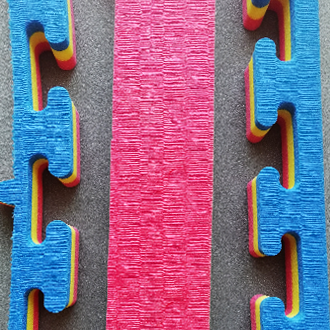

Materials that can be cut

Cutting Shapes

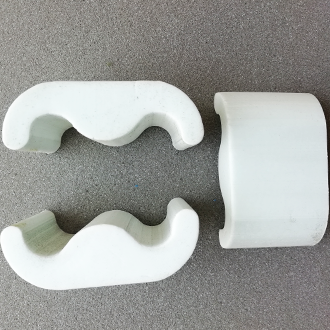

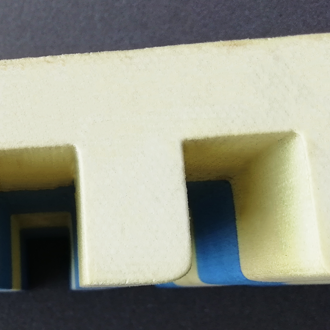

- Cutting samples

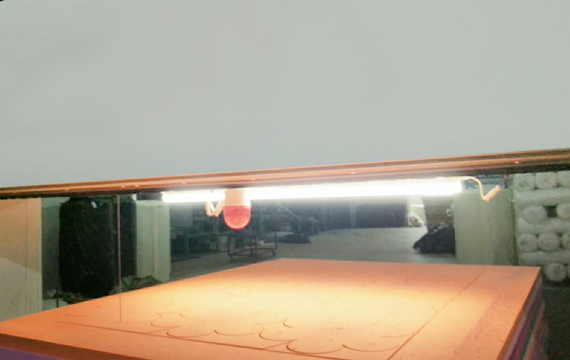

Machine installation pictures (3)

Lorem Ipsum Dummy Text

Loading pictures

Related products (4)

It won’t generate dust because the oscillating blade effectively controls the scattering of materials during cutting. However, the specific situation may also depend on the type and density of the materials being cut

The main vulnerable parts of this machine include the blade belt and clamp teeth. The replacement time for the blade belt and clamp teeth is not fixed and is usually determined by the type of foam being cut and the machine’s working hours. In addition, there are some other vulnerable parts, such as small springs and dampers, which are typically replaced every three months.

The lifespan of the machine depends on several factors, including usage frequency, the hardness of the cutting materials, and the level of maintenance.

If the machine is properly maintained and used according to the manufacturer’s recommendations, it can typically last around 10 years.

We will send this machine in 15days after receiving 30% deposit and will deliver the goods in the container after receiving the rest 70% balance .

No, it can cut all 2D shapes but only some of 3D shapes.

.png)