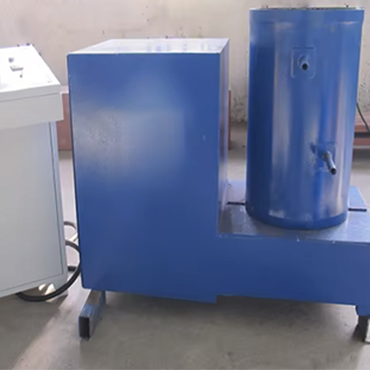

Raytech CNC foam cutting machine

We’ve developed a CNC foam contour cutting machine, a large-scale cutting device with independent intellectual property rights, based on the experience gained from similar foreign products.

This equipment utilizes industrial computers to control AC servo motors, enabling efficient cutting of intricate shapes. Ideal for foam processing and furniture manufacturing, it addresses the inefficiency and labor-intensive nature of traditional mechanical die-cutting methods for foam shapes

It significantly boosts production efficiency, with one machine equivalent to the output of 4-5 workers. We offer a variety of model options tailored to different industries and materials. Choose the model that best suits your needs

Lorem ipsum dolor sit amet (3)

Lorem Ipsum Dolor Sit Amet Consectetur

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua. Lorem ipsum dolor sit amet.

Lorem ipsum dolor sit (3)

Lorem ipsum dolor sit (3)

Sed do Uinsmod Tempor Incididunt ut Labore

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore etfer dolore magna aliqua.

Sed do Uinsmod Tempor Incididunt ut Labore

because the circular blade is hanging on the wheel, driven by the motor for high-speed cutting. In this setup, even a slight deviation in the blade’s position due to the circular motion can result in less accurate cuts.

On the other hand, oscillation blades are fixed at both ends and are driven by the motor to rapidly oscillate back and forth for cutting. During cutting, the blade is tightly held, preventing any deviation. Therefore, oscillation blades tend to have higher cutting precision, ensuring more accurate cutting tasks

consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.

consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.

consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.

consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.