Product By Features

It is well-suited for cutting block products and is capable of efficiently cutting various shapes, including pyramid and irregular forms, as well as both two-dimensional and basic three-dimensional profiles

High cutting speed, equipped with safety protection devices and an automatic blade sharpening system, capable of cutting composite foam and various other materials, dust-free operation.

The machine offers high cutting precision and strong cutting force, making it suitable for cutting high-hardness materials. It is equipped with a dust extraction bag to ensure a clean environment in the workshop

Fast processing speed, fewer vulnerable parts, high cutting accuracy, dust-free operation, low noise, and support for the replacement of both toothed and toothless cutters

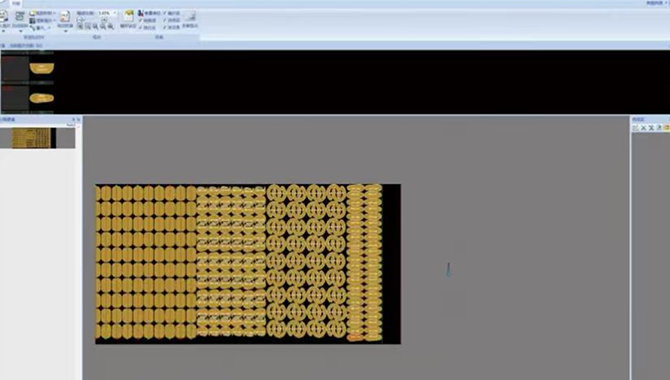

The machine achieves high-precision cutting, making it particularly suitable for intricate carving or complex shapes. It can cut various types of foam expecially EPS

Hot wire cutting produces a relatively smooth cut without leaving noticeable uneven marks. Additionally, hot wire cutting typically generates lower noise levels

Product Feature Box

Foam contour cutting machines often feature automated operation systems, enabling automated cutting processes. Through pre-set programs and parameters, they can easily improve production efficiency.

Foam contour cutting machines are used for cutting different types of foam materials, such as polyurethane foam, polyester foam, polyethylene foam, and more.

Dust-free cutting creates a cleaner and safer working environment for operators. It ensures the health and well-being of workers. It provides lots of environmental benefits.

By replacing human labor with machines, companies can reduce labor costs. The initial investment and maintenance expenses for machines are often lower.

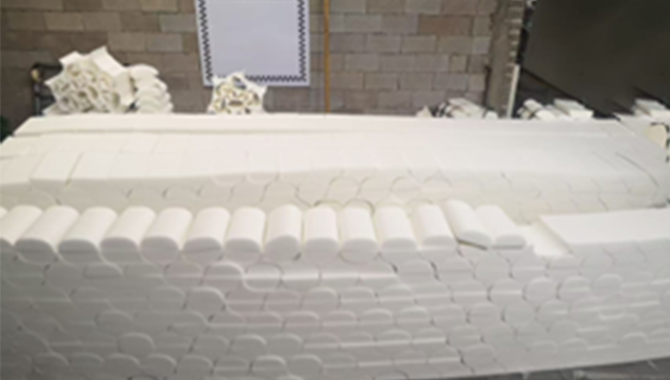

A scaled production workshop

The production workshop is equipped with advanced manufacturing equipment to ensure an efficient and high-quality production process.

A stable supply chain

A stable supply chain ensures a consistent and reliable provision of raw materials and components, maintaining the continuity of production and ensuring high product quality

Consumable parts warehouse

We have a dedicated workshop for the production of vulnerable parts to ensure timely supply and maintain sufficient inventory. We are well-prepared for the supply of vulnerable parts

Rigorous testing before delivery

We conduct rigorous testing on each machine before leaving the factory to ensure top-notch quality. The crucial motors and electrical components of the machines are sourced from renowned international brands, guaranteeing reliability and performance.