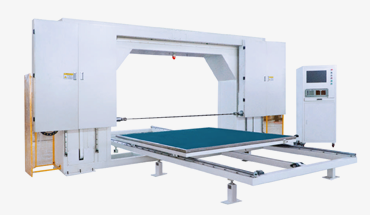

RT-622

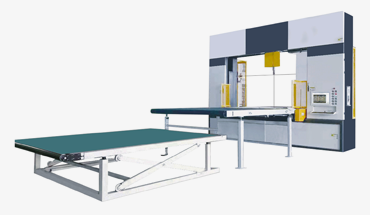

RT-622 (dual-axis contour cutting machine ), which is the wise choice for large foam manufacturers. The two circular blades of the dual-axis contour cutting machine can run at high speed, with the horizontal blade quickly slicing and the vertical blade swiftly cutting shapes.

- Dual Blade Belts: Equipped with two blade, the machine can efficiently cut various shapes, enhancing production capacity to handle more orders promptly. This ensures quick delivery to customers, meeting diverse demands for large orders

- Versatile Material Cutting: The circular blade design enables the machine to cut a wide range of materials, meeting different cutting requirements from customers and expanding the capacity to take on more orders

- Low Equipment Wear: The durable blades have fewer vulnerable parts, resulting in low maintenance costs and minimizing additional financial expenses for the company

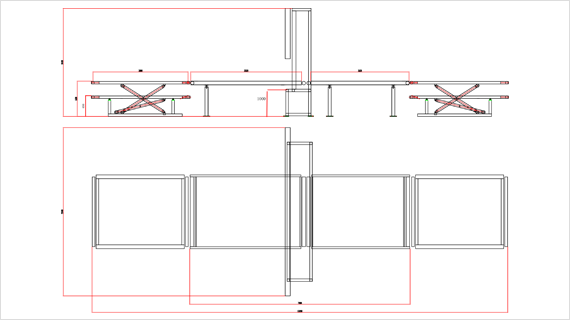

Dual-axis contour cutting machine RT-622

RT-622 (horizontal oscillating blade contour cutter) is the fastest and most efficient machine among all models. Throughout the cutting process, it generates no dust, and the two liftingtables at the front and rear can be seamlessly integrated with other machines to form an intelligent assembly line, making the entire operation smoother and more efficient.

This machine is the optimal choice for large sponge factories aiming to enhance the efficiency of their production lines.

The foam contour cutting machine is not just a choice for the current increase in order volume but also a reliable partner for the future of large foam factories. We will continuously upgrade and improve this model to meet the evolving needs of customers. Considering the personalized requirements of our customers, we also provide customized services to offer more flexible solutions. Choose dual-axis contour cutting machine for an efficient and productive future.

Technical Data

- Tab1

| Machine Weight (T) | 5.2 |

| Total Power (KW) | 13 |

| Maximum Cutting Size (mm) | 3000*2200*1100 |

| Blade Size (mm) | 14000*3.5*0.6 |

| Cutting Speed (m/min) | 0~40 |

| AC Power Supply | 220V/380V/415V 50/60HZ |

| Accuracy(mm) | ±1 |

| Workbench Structure | Conveyor |

| Adjust Blade to Zero | Installed |

| Self-diagnostic Status | Installed |

three unique advantages

Rotary working table

Horizontal oscillating blade contour cutter is crucial for cutting 3D models accurately. It eliminates the manual hassle of repositioning the foam. This worktable can rotate the foam block, making it easy to cut different sides. This simplifies foam production and meets various cutting needs

Small footprint

RT(Horizontal oscillating blade contour cutter) is easy to move; you can relocate it wherever needed, making it convenient for production in various corners of the workshop

long lifespan

less wearable components , simply follow the recommendations of our after-sales personnel to clean the machine before leaving work each day, ensuring the machine’s usability for over 10 years

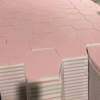

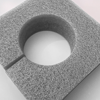

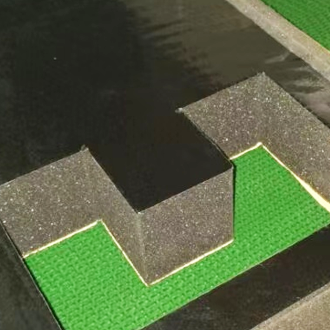

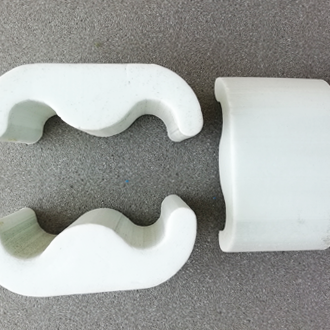

Materials that can be cut

Cutting Shapes

- Cutting samples

Machine installation pictures (3)

Lorem Ipsum Dummy Text

Loading pictures

Related products (4)

It won’t generate dust because the oscillating blade effectively controls the scattering of materials during cutting. However, the specific situation may also depend on the type and density of the materials being cut

The main vulnerable parts of this machine include the blade belt and clamp teeth. The replacement time for the blade belt and clamp teeth is not fixed and is usually determined by the type of foam being cut and the machine’s working hours. In addition, there are some other vulnerable parts, such as small springs and dampers, which are typically replaced every three months.

The lifespan of the machine depends on several factors, including usage frequency, the hardness of the cutting materials, and the level of maintenance.

If the machine is properly maintained and used according to the manufacturer’s recommendations, it can typically last around 10 years.

We will send this machine in 15days after receiving 30% deposit and will deliver the goods in the container after receiving the rest 70% balance .

No, it can cut all 2D shapes but only some of 3D shapes.

.png)