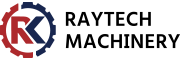

RT-R620

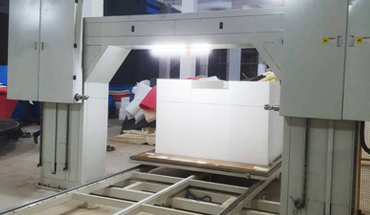

RT-R620 (horizontal contour cutting machine) achieves a cutting speed of up to 60 meters per minute. It not only improves production efficiency but also ensures accuracy, effectively reducing foam waste and increasing the company’s profit . If you have large cutting different shapes requirement , this machine is the best choice

- Robust Structure: Through advanced reinforcement techniques, we’ve strengthened the machine’s structure for increased durability.

- Reliable Performance:The main motor , servo motor and pneumatic component are all imported brand to gurantee the high-quality product .

- Long Service Life: The machine leaving the factory have a lifespan of around 7 years. With proper maintenance, It can be used for an extended period

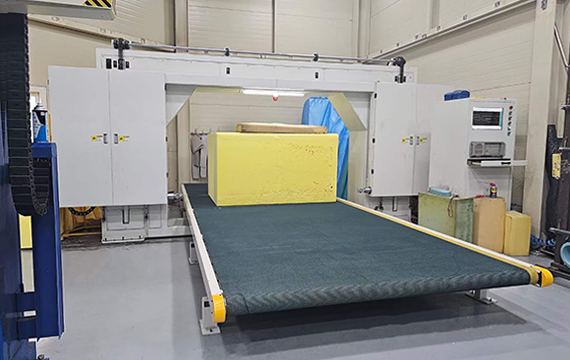

horizontal contour cutting machine (RT-R620)

RT-R620(horizontal contour cutting machine )operates with low noise, eliminating any unfriendly sounds that could harm workers’ mental well-being during the cutting process . Additionally, it produces no dust, adhering to green environmental standards, keeping the workshop clean, and providing a friendly working environment for employees.

The blade belt is durable, with low equipment consumption and maintenance costs, minimizing additional burdens on the company.

If you have a large volume of cutting orders with irregular and 3D shapes, and your previous production couldn’t keep up, then this machine is a very suitable choice

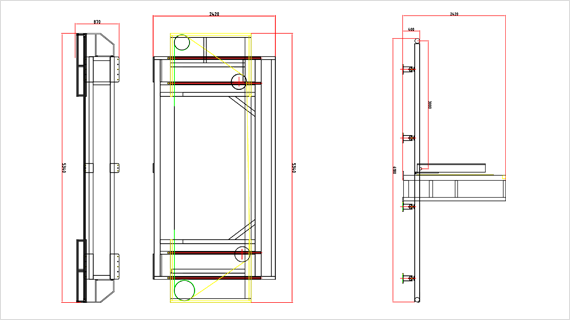

Technical Data

- Tab1

| Machine Weight (T) | 3.2 |

| Total Power (KW) | 13 |

| Maximum Cutting Size (mm) | 2200*2200*1200 |

| Blade Size (mm) | 12000*3.5*0.6 |

| Cutting Speed (m/min) | 0~40 |

| AC Power Supply | 220V/380V/415V |

| Accuracy(mm) | ±1 |

| Workbench Structure | Flat Turntable |

| Adjust Blade to Zero | Installed |

| Self-diagnostic Status | Installed |

three unique advantages

Low Power Consumption

Horizontal contour cutting machine(RT-R620)only consumes around 4 to 5 kWh per hour, and even working a full 12-hour day won’t cost you more than about 50 kWh. This won’t pose a significant economic burden for you.

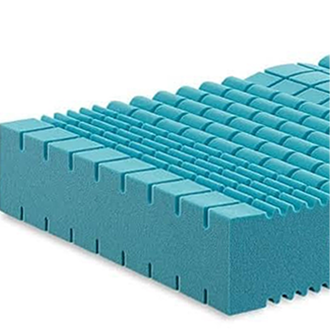

Two Blade Options

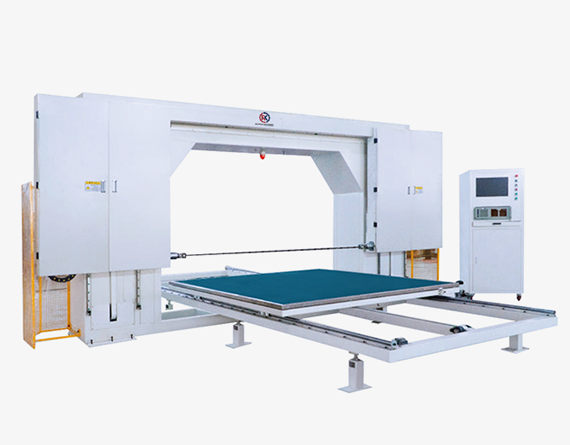

You can choose toothed or non-toothed blades based on different materials. It can cut all 2D shapes and simple 3D shapes, meeting various production needs.

Whether it’s a toothed blade or a toothless blade ,the blade replacement is simple . Following our technician guidance and with skilled operation, one blade can be replaced within 3 minutes

Simple Operation

The software is user-friendly, and with basic computer skills and guidance from the master, you’ll quickly learn to operate the machine

optional conveyor worktable

You can choose the most suitable one based on your production needs, foam block length, and cutting shapes.

Materials that can be cut

Cutting Shapes

- Cutting samples

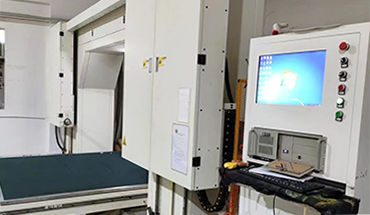

Machine installation pictures (3)

Lorem Ipsum Dummy Text

Loading pictures

Related products (4)

It won’t generate dust because the oscillating blade effectively controls the scattering of materials during cutting. However, the specific situation may also depend on the type and density of the materials being cut

The main vulnerable parts of this machine include the blade belt and clamp teeth. The replacement time for the blade belt and clamp teeth is not fixed and is usually determined by the type of foam being cut and the machine’s working hours. In addition, there are some other vulnerable parts, such as small springs and dampers, which are typically replaced every three months.

The lifespan of the machine depends on several factors, including usage frequency, the hardness of the cutting materials, and the level of maintenance.

If the machine is properly maintained and used according to the manufacturer’s recommendations, it can typically last around 10 years.

We will send this machine in 15days after receiving 30% deposit and will deliver the goods in the container after receiving the rest 70% balance .

No, it can cut all 2D shapes but only some of 3D shapes.

.png)

.png)