RT-HR23

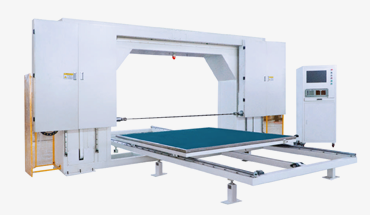

RT-HR23(Horizontal oscillating blade contour cutter ) can cut all 2D shapes and some 3D foam shapes that other models may not be able to cut.

- Easy to install :Your team can easily install this machine within 3 days by following our installation guide video

- Easy to learn: As long as you are familiar with computer operations, you can learn the basic operations of the machine within three days.

- Easy to operate:The interface is user-friendly, making it simple and efficient

- Easy to maintain:The machine has few vulnerable parts, and its failure rate is low, requiring only simple maintenance

Horizontal contour cutting machine RK-HR23

RT-HR23(horizontal oscillating blade contour cutter) adopts vibrating knife cutting technology, where its working principle involves two casings driving the blade belt in a reciprocating left and right motion.

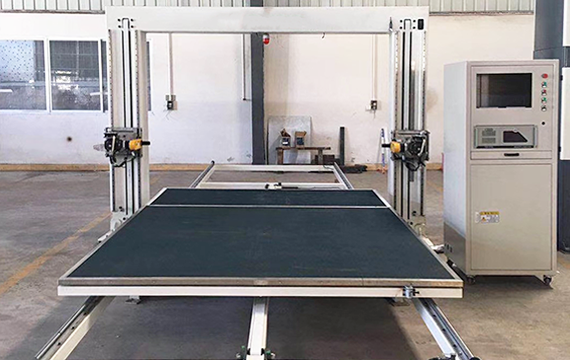

It can efficiently and precisely cut various foam materials, including PU FOAM, Rebonded FOAM, sticky foam, and more. The worktable of the machine can rotate 90 degrees, enabling it to cut 3D shapes that other models cannot handle.

The blade replacement process is simple and can be completed within 2 minutes. In manual cutting mode, it comes equipped with a remote control for easy operation.

The entire process is dust -free cutting , making it environmentally friendly

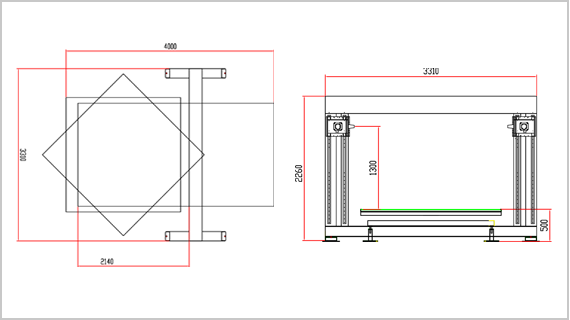

If your foam blocks are 2200mm in length and 2200mm in width, and you need to cut high-precision 3D shapes, then this foam contour cutting machine RT-HR23 is the suitable choice

Technical Data

- Tab1

| Machine Weight (T) | 3.2T |

| Total Power (KW) | 8 |

| Maximum Cutting Size (mm) | 2200*2200*1250 |

| Blade Size (mm) | 2530*3*0.6 |

| Cutting Speed (m/min) | 0~15 |

| AC Power Supply | 220V/380V/415V |

| Accuracy(mm) | ±0.5 |

| Workbench Structure | Automatic / Manual Turntable |

| Adjust Blade to Zero | Installed |

| Self-diagnostic Status | Installed |

three unique advantages

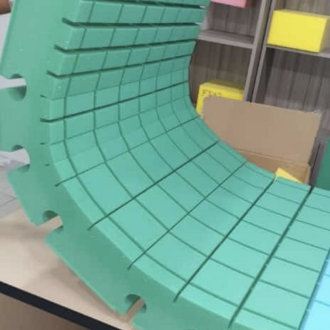

Rotary working table

Horizontal oscillating blade contour cutter is crucial for cutting 3D models accurately. It eliminates the manual hassle of repositioning the foam. This worktable can rotate the foam block, making it easy to cut different sides. This simplifies foam production and meets various cutting needs

Small footprint

RT(Horizontal oscillating blade contour cutter) is easy to move; you can relocate it wherever needed, making it convenient for production in various corners of the workshop

long lifespan

less wearable components , simply follow the recommendations of our after-sales personnel to clean the machine before leaving work each day, ensuring the machine’s usability for over 10 years

multiple options

If the foam block length exceeds 2200mm(between 2200mm and 2600mm), there is a requirement for cutting three-dimensional shapes, this model can fully meet the demand.

multiple options

If the foam block length exceeds 3000mm, without the need for cutting three-dimensional shapes but requiring cutting of patterns and sheets with a thickness of more than 3mm, this model can meet the requirements.

Materials that can be cut

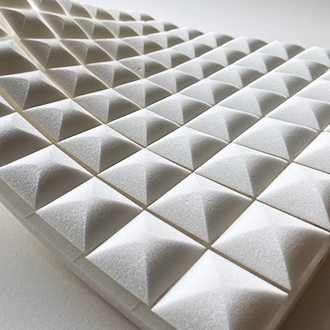

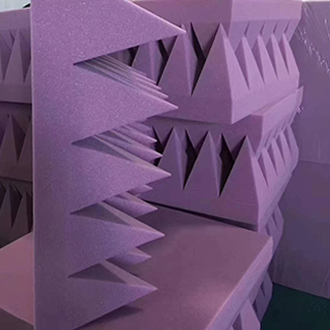

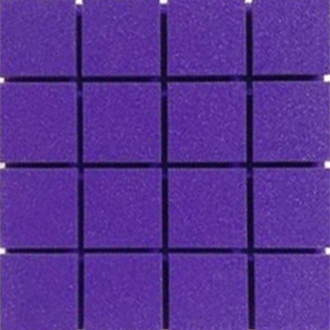

Cutting Shapes

- Cutting samples

Group photo of customer during machine installation (3)

Lorem Ipsum Dummy Text

Loading pictures

Related products (4)

It won’t generate dust because the oscillating blade effectively controls the scattering of materials during cutting. However, the specific situation may also depend on the type and density of the materials being cut

The main vulnerable parts of this machine include the blade belt and clamp teeth. The replacement time for the blade belt and clamp teeth is not fixed and is usually determined by the type of foam being cut and the machine’s working hours. In addition, there are some other vulnerable parts, such as small springs and dampers, which are typically replaced every three months.

The lifespan of the machine depends on several factors, including usage frequency, the hardness of the cutting materials, and the level of maintenance.

If the machine is properly maintained and used according to the manufacturer’s recommendations, it can typically last around 10 years.

We will send this machine in 15days after receiving 30% deposit and will deliver the goods in the container after receiving the rest 70% balance .

No, it can cut all 2D shapes but only some of 3D shapes.