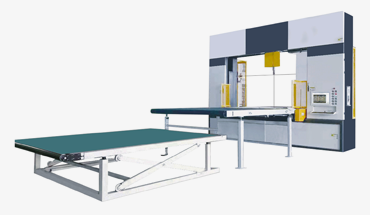

RT-MT1

Mattress tape edge machine is a crucial part of the production process. It not only stitches the edges of the mattress but also secures all surfaces, ensuring structural integrity. Choosing a high-quality mattress tape edge machine is essential for superior results.

- Low vibration and noise design enhances operator comfort.

- Worktable height and machine head angle adjustable via buttons for convenience and flexibility.

- Knee control lever or manual operation allows flexible and precise edging.

- High efficiency, completing edging on one mattress every 6 minutes.

Mattress Tape Edge Machine RT-MT1

RT-MT1 Mattress tape edge machine is a crucial part of the production process. It not only stitches the edges of the mattress but also secures all surfaces, ensuring structural integrity. Choosing a high-quality mattress tape edge machine is essential for superior results.

Technical Data

- Tab1

| Machine Weight (T) | 600kg |

| Total Power (KW) | 1.2kw |

| Head Working Angle | 35°- 55° |

| Mattress Thickness Sewing Range | 20-420mm |

| Worktable Lifting Range | 260mm |

| Automatic corner deceleration | yes |

| Worktable lifting Method | Electric |

| Worktable surface dimensions | 1600*2000mm |

| Head Speed | 1100-3000r/min |

| Travel speed | 6-16m/min |

| Production Efficiency | 15pcs/h |

| Outer packages size | 2250*1750*800mm |

three unique advantages

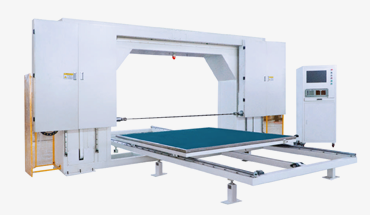

Rotary working table

Electrically Adjustable Worktable & Automatic Head Tilt

The electric lifting worktable and auto-adjustable machine head reduce operator workload and enhance production efficiency.

Small footprint

Built-in Rotary Electrical Power Supply

Compact and space-saving design requires no special installation, easily integrates into existing production lines, and ensures stable operation.

long lifespan

Variable Frequency Speed Regulation & Corner Auto-Slowdown

Simplifies operation, reduces maintenance needs, and guarantees efficient production while lowering costs.

Materials that can be cut

Cutting Shapes

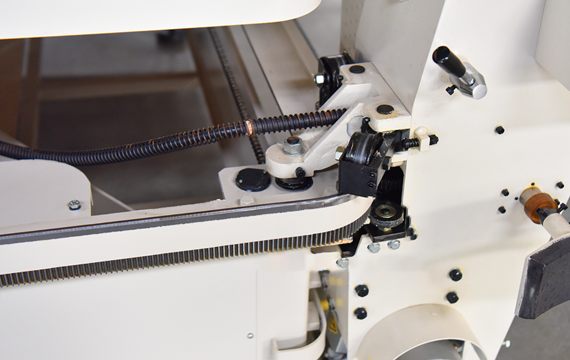

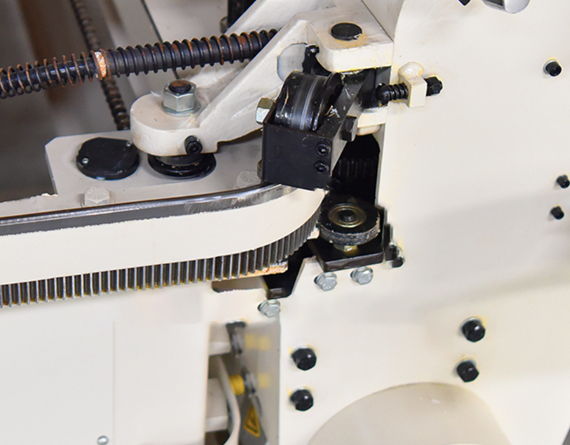

Machine installation pictures (3)

Lorem Ipsum Dummy Text

Mattress Tape Edge Machine

Loading pictures

Related products (4)

It won’t generate dust because the oscillating blade effectively controls the scattering of materials during cutting. However, the specific situation may also depend on the type and density of the materials being cut

The main vulnerable parts of this machine include the blade belt and clamp teeth. The replacement time for the blade belt and clamp teeth is not fixed and is usually determined by the type of foam being cut and the machine’s working hours. In addition, there are some other vulnerable parts, such as small springs and dampers, which are typically replaced every three months.

The lifespan of the machine depends on several factors, including usage frequency, the hardness of the cutting materials, and the level of maintenance.

If the machine is properly maintained and used according to the manufacturer’s recommendations, it can typically last around 10 years.

We will send this machine in 15days after receiving 30% deposit and will deliver the goods in the container after receiving the rest 70% balance .

No, it can cut all 2D shapes but only some of 3D shapes.

.png)