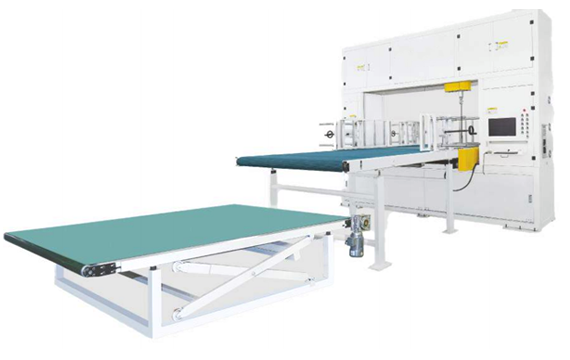

RT-621

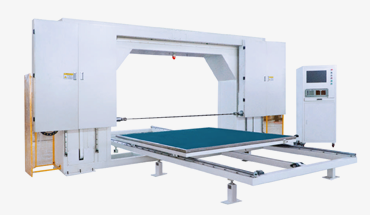

The foam contour cutter has three models: vertical blade, horizontal blade, and double blades. Among them, RT-621 (vertical contour cutting machine) is the preferred choice for large sponge factories. It can cut over 20 large sponge blocks in a day, making it a popular choice for factories with high order volumes.

- Fast Speed: The machine can run at a speed of up to 60 meters per minute, and the cutting speed varies depending on the specific product. Overall, it’s much faster than vibrating blade machines

- Smooth Cutting Surface: When using a toothless blade belt for cutting, the surface of cutting material remains smooth without any visible blade marks

- Sharpening Device: The sharpening device helps the toothless blade belt maintain sharpness during the cutting process, ensuring faster and more efficient cutting.

Vertical contour cutting machine RT-621

The revolving blade cutter has a cutting speed 4-5 times faster than the oscillating blade machine, but its precision is only +/-1. If you can accept this level of precision and need a fast machine, consider this one.

Moreover, the machine is suitable for cutting sheets, with a maximum cutting thickness of 1100mm. Additionally, it can trim the four edges of sponge sheets and large sponge blocks. If you need to cut sheets and trim edges simultaneously, this machine is the preferred choice

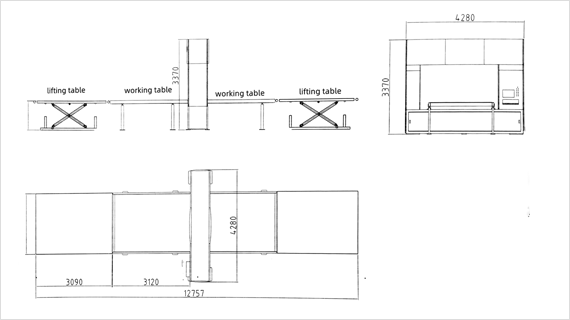

Also it is equipped with two lifting platforms, with one platform used for material transportation and cutting, and the other for packaging after the cutting process. The vertical contour cutting machine can be seamlessly integrated with other machine models to form an intelligent assembly line, significantly improving overall work efficiency.

It’s worth noting that this flexible combination allows the production line to adapt to various production needs, providing a reliable solution for large sponge factories.

Technical Data

- Tab1

| Machine Weight (T) | 4.2 |

| Total Power (KW) | 13 |

| Maximum Cutting Size (mm) | 3000*2200*1100 |

| Blade Size (mm) | 14000*3.5*0.6 |

| Cutting Speed (m/min) | 0~60 |

| AC Power Supply | 220V/380V/415V 50/60HZ |

| Accuracy(mm) | ±1 |

| Workbench Structure | Conveyor |

| Adjust Blade to Zero | Installed |

| Self-diagnostic Status | Installed |

three unique advantages

Equipped with Blade Breakage Protection System

This system helps reduce equipment damage, enhancing the safety of the production line. It also lowers the costs associated with maintenance and repairs, ensuring efficient and secure operations.

Simple Structural Design for the Rotary Blade Section

The design of the revolving blade section is straightforward, making it easy to maintain. This simplification streamlines the work for employees, making maintenance and repairs more convenient

Low Noise Levels during Cutting

The machine produces relatively low noise levels during the cutting process, providing employees with a pleasant working environment. This not only benefits work efficiency and concentration but also contributes to maintaining the psychological well-being and overall job satisfaction of the staff

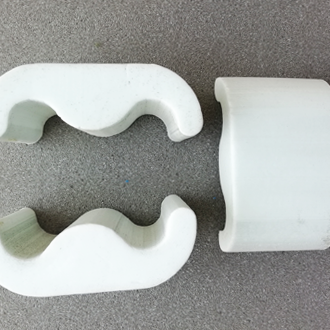

Model Option for EPE foam

There is a model specifically designed for cutting EPE foam with a cutting height of 600mm. This model is customized for the needs of EPE foam machines.

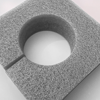

Materials that can be cut

Cutting Shapes

- Cutting samples

Machine installation pictures (3)

Lorem Ipsum Dummy Text

Loading pictures

Related products (4)

It won’t generate dust because the oscillating blade effectively controls the scattering of materials during cutting. However, the specific situation may also depend on the type and density of the materials being cut

The main vulnerable parts of this machine include the blade belt and clamp teeth. The replacement time for the blade belt and clamp teeth is not fixed and is usually determined by the type of foam being cut and the machine’s working hours. In addition, there are some other vulnerable parts, such as small springs and dampers, which are typically replaced every three months.

The lifespan of the machine depends on several factors, including usage frequency, the hardness of the cutting materials, and the level of maintenance.

If the machine is properly maintained and used according to the manufacturer’s recommendations, it can typically last around 10 years.

We will send this machine in 15days after receiving 30% deposit and will deliver the goods in the container after receiving the rest 70% balance .

No, it can cut all 2D shapes but only some of 3D shapes.