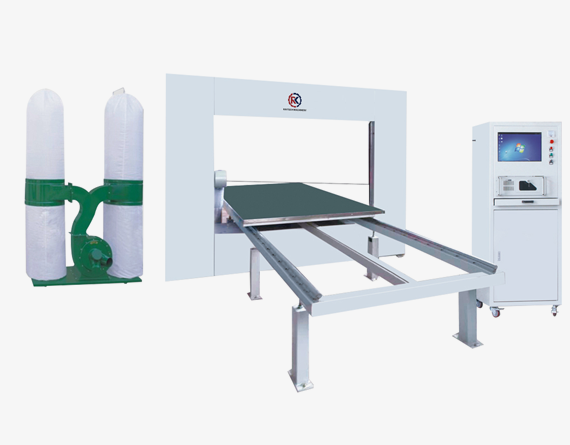

RT-R630

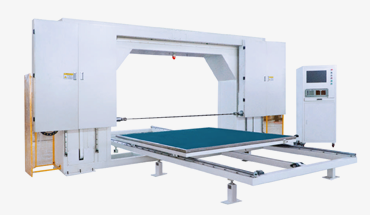

RT-630(Horizontal fast wire cutting machine ) is our horizontal wire blade, designed to cut all types of rigid foam. The horizontal blade can cut the entire block of rigid foam into the desired shapes horizontally.

If you’re looking for a machine to cut irregular shapes from whole blocks of rigid foam, then this model is highly suitable.

- Stable Performance: The machine uses components from well-known brands both domestically and internationally, ensuring stable quality and performance. This provides customers with an outstanding user experience

- Versatility: The machine can meet various cutting needs, including angle and curve cutting, catering to diverse requirements from customers

-

Precision Cutting: Utilizing a fast-friction blade for material cutting, achieving precision within a range of plus or minus 0.5. This meets high standards for cutting requirements

-

Long Machine Lifespan: Cleaning the machine’s hygiene before leaving work each day contributes to extending the machine’s lifespan

Horizontal contour cutting machine RK-R610

RT-630(horizontal fastwire cutting machine) can precisely cut entire blocks of rigid foam into any desired shapes. It achieves this by utilizing a horizontal blade to achieve the precise cutting of materials into various required shapes.

The materials cut by this method find wide applications in the construction and packaging industries.

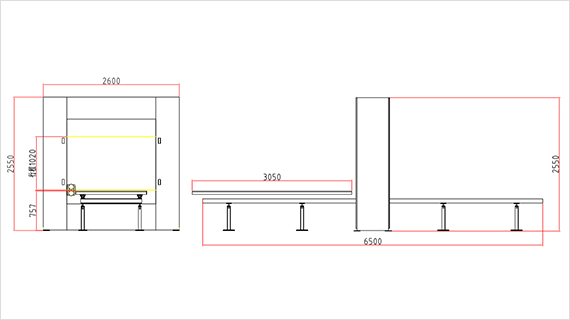

Technical Data

- Tab1

| Machine Weight (T) | 2.8 |

| Total Power (KW) | 8 |

| Maximum Cutting Size (mm) | 2500*1600*1000 |

| Blade Size (mm) | 11300 |

| Cutting Speed (m/min) | 0~10 |

| AC Power Supply | 220V/380V/415V 50/60HZ(3phase) |

| Accuracy(mm) | ±0.5 |

| Workbench Structure | Conveyor/Rotary worktable |

| Adjust Blade to Zero | 6 Bar pressure |

| Self-diagnostic Status | Installed |

three unique advantages

Versatile Shape Cutting

The horizontal wire excels at precise cutting of rigid foam into various shapes, meeting the demanding requirements of different customer orders.

Flexible Worktable Options

The worktable offers two choices – conveyor belt and rotating table. Users can select the suitable option based on production needs and the type of products to be cut

Compact Footprint

Occupying just 16 square meters, it can be placed in a corner of the workshop, saving space and maximizing the utilization of this small machine

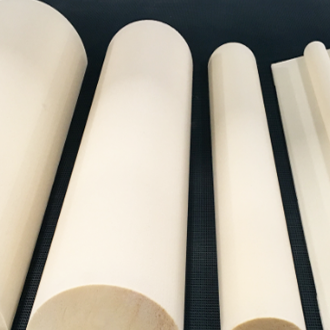

Materials that can be cut

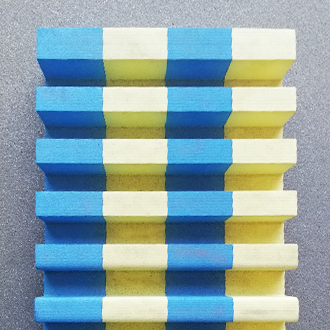

Cutting Shapes

- Cutting samples

Machine installation Pictures (3)

Lorem Ipsum Dummy Text

Loading pictures

Related products (4)

It won’t generate dust because the oscillating blade effectively controls the scattering of materials during cutting. However, the specific situation may also depend on the type and density of the materials being cut

The main vulnerable parts of this machine include the blade belt and clamp teeth. The replacement time for the blade belt and clamp teeth is not fixed and is usually determined by the type of foam being cut and the machine’s working hours. In addition, there are some other vulnerable parts, such as small springs and dampers, which are typically replaced every three months.

The lifespan of the machine depends on several factors, including usage frequency, the hardness of the cutting materials, and the level of maintenance.

If the machine is properly maintained and used according to the manufacturer’s recommendations, it can typically last around 10 years.

We will send this machine in 15days after receiving 30% deposit and will deliver the goods in the container after receiving the rest 70% balance .

No, it can cut all 2D shapes but only some of 3D shapes.